Solid surface integrated tops have revolutionized the design and functionality of commercial spaces. Known for their seamless appearance, durability, and hygiene, these tops are tailored to meet the specific needs of various industries, including hospitality, healthcare, and retail. The customization of solid surface integrated tops involves several advanced techniques, primarily monolithic casting, seamless joint fabrication, and thermoforming. However, there are additional considerations and methods that enhance the customization process, ensuring that each piece is both functional and aesthetically pleasing.

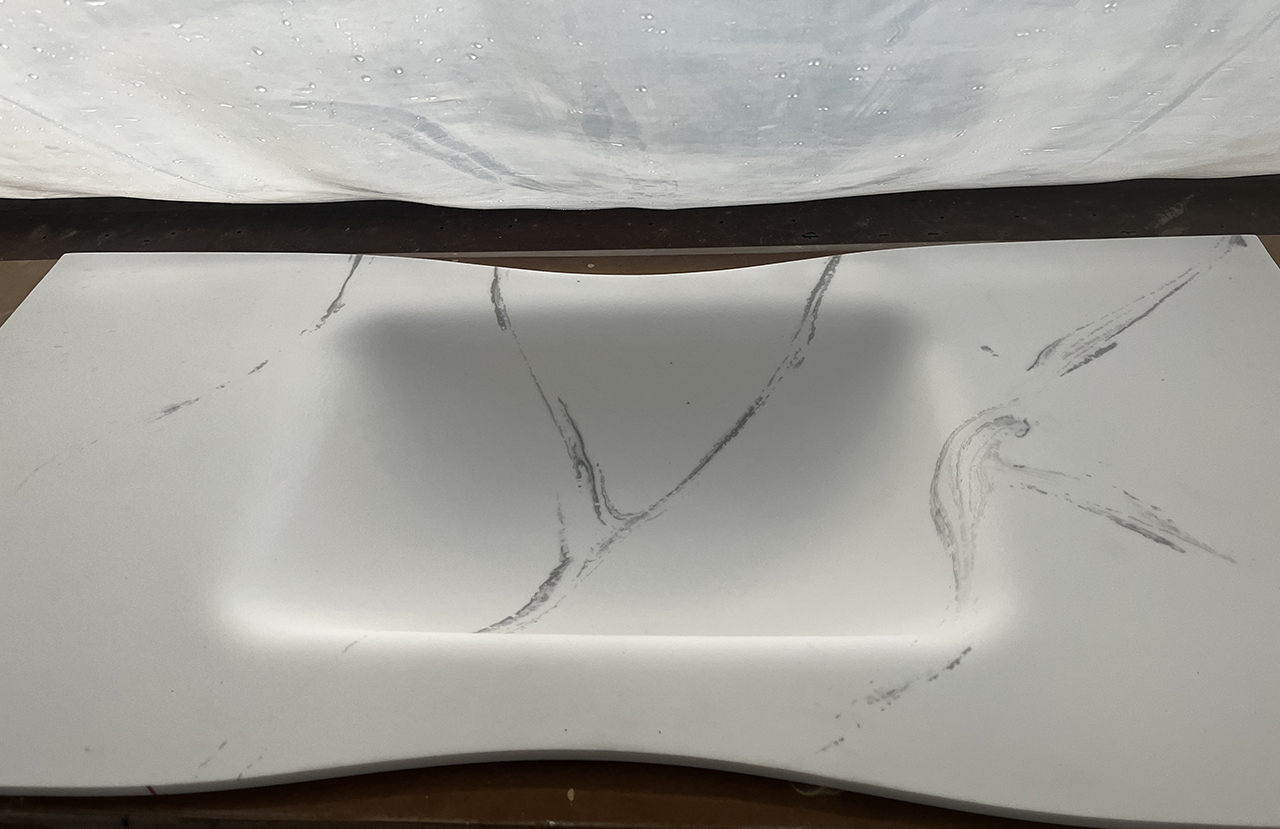

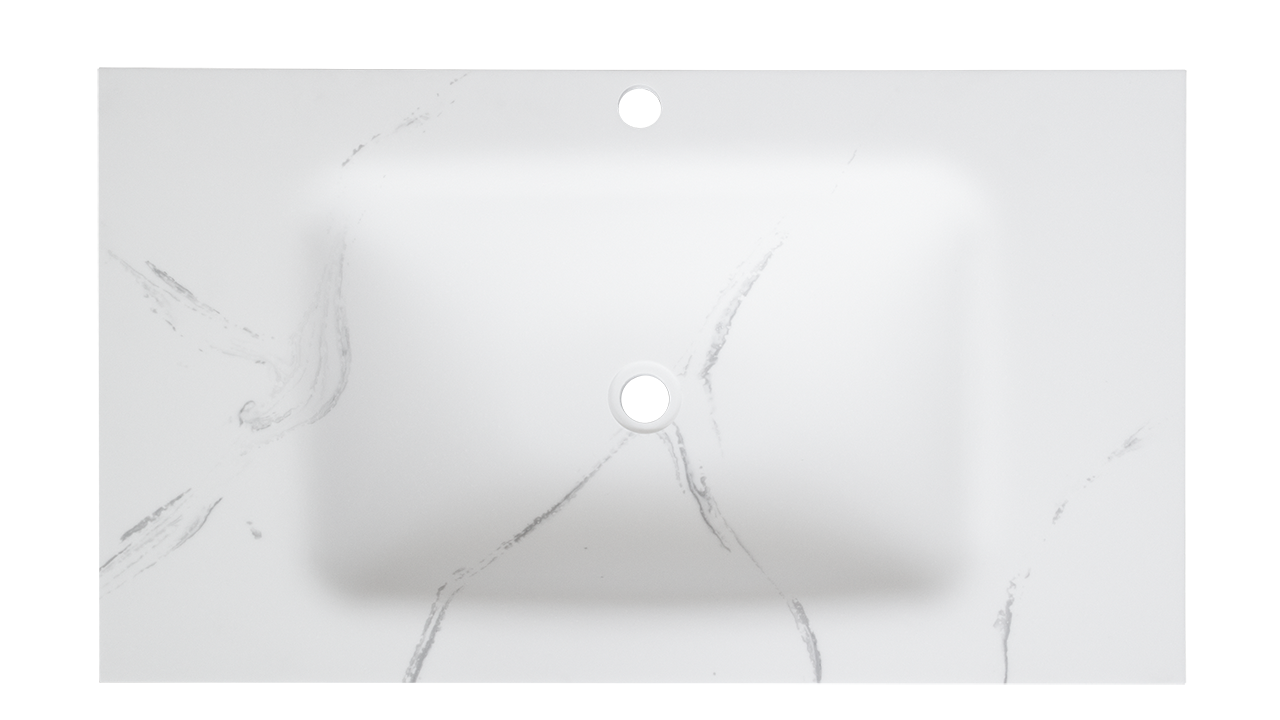

Monolithic Casting for Seamless Integration

Monolithic casting involves creating a single, cohesive piece that integrates the top and sink. This technique ensures a sleek, uninterrupted surface, enhancing both the visual appeal and hygiene of the vanity top. The absence of seams prevents the accumulation of dirt and bacteria, making it an ideal choice for environments that require strict cleanliness standards, such as hospitals and commercial kitchens. This method is perfect for achieving a minimalist, modern look while maintaining practical functionality.

Seamless Joint Fabrication for Custom Designs

Seamless joint fabrication allows for the assembly of multiple solid surface pieces into a unified structure without visible seams. This technique is particularly useful for creating large or uniquely shaped vanity tops that wouldn't be feasible with a single cast. The joints are chemically bonded and polished to be virtually invisible, maintaining the seamless aesthetic. This method provides flexibility in design, enabling custom configurations and installations that fit perfectly into diverse commercial spaces.

Thermoforming for Dynamic Shapes

Thermoforming involves heating solid surface sheets until they become pliable, allowing them to be molded into various shapes. This process is ideal for creating complex, organic forms that add a unique element to the commercial space. The ability to produce curved, fluid designs makes thermoforming a favorite among designers aiming to introduce innovative and striking elements into their projects. This technique is often used in high-end retail and hospitality settings where visual impact is paramount.

Additional Considerations in Customization

Beyond the primary fabrication techniques, several other factors and methods contribute to the customization of solid surface integrated tops:

Design Consultation and Collaboration

Customization begins with a thorough design consultation where designers and clients discuss their vision, functional needs, and aesthetic preferences. Collaboration between designers, architects, and fabricators ensures that the final product meets the exact specifications required for the commercial space. This collaborative approach helps in selecting the appropriate materials, colors, and finishes that align with the overall design theme.

Digital Modeling and Prototyping

Advanced digital modeling software allows for precise design and visualization of the vanity tops before fabrication begins. 3D modeling and prototyping enable designers to experiment with different shapes, sizes, and configurations, ensuring that the final product fits perfectly within the intended space. This step is crucial for identifying any potential issues and making necessary adjustments before production.

Custom Finishes and Textures

Solid surface materials can be customized with a variety of finishes and textures to match the desired look and feel of the commercial space. From high-gloss to matte finishes, and from smooth surfaces to textured patterns, the customization options are vast. These finishes not only enhance the aesthetic appeal but also contribute to the practicality and usability of the surfaces.

Integrated Features and Accessories

In addition to customizing the shape and design, solid surface integrated tops can incorporate various features and accessories to enhance functionality. Integrated drainboards, soap dishes, backsplashes, and even lighting elements can be seamlessly incorporated into the design. These features are particularly beneficial in commercial environments where functionality and efficiency are as important as aesthetics.

The customization of solid surface integrated tops involves a blend of advanced fabrication techniques, collaborative design processes, and attention to detail. Techniques like monolithic casting, seamless joint fabrication, and thermoforming provide the foundation for creating unique and functional designs. Additional considerations such as design consultation, digital modeling, custom finishes, integrated features, and sustainable practices further enhance the ability to tailor these surfaces to the specific needs of commercial spaces. By leveraging these methods, manufacturers like Gelandy offer comprehensive solutions that meet both the aesthetic and practical demands of modern commercial environments.