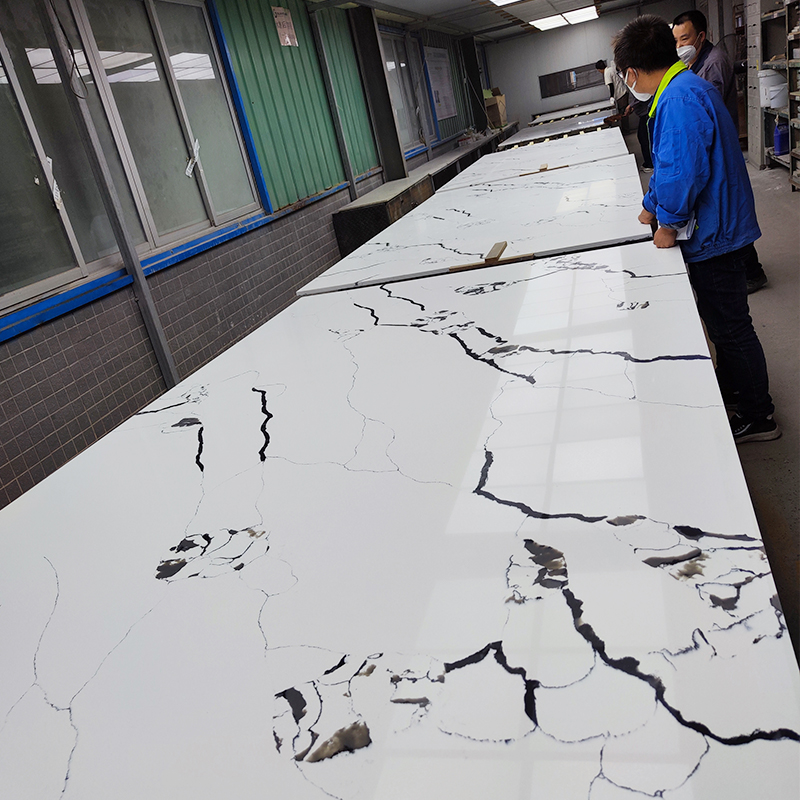

Gelandy solid surface products can be seamlessly joined using our specially formulated adhesives. On the back side, the adhesive is visible before polishing, but once finished, the front shows no visible seams, giving a flawless, continuous appearance. For customers who require it, we offer custom-colored adhesives that perfectly match the surface, ensuring not only a seamless visual effect but also a strong and durable bond. This makes the solid surface installations both aesthetically perfect and structurally reliable.

How to Choose the Right Solid Surface Adhesive and What to Consider When Purchasing and Exporting?

Solid surface seamless jointing is one of the key advantages of this material. High-quality fabrication and installation can only be achieved when the jointing process is executed correctly, which makes the adhesive a crucial part of production. A good adhesive not only supports excellent workmanship but also ensures strong bonding strength for long-term durability.

The question many customers ask is:

“How to purchase the right solid surface adhesive, and what should be considered during adhesive procurement and export?”

1. Why the Adhesive Matters in Solid Surface Jointing

Seamless joints are one of the biggest selling points of solid surface materials. To achieve this effect, the adhesive must match the sheet color precisely and allow for smooth sanding and finishing. A poor-quality or mismatched adhesive may cause visible seams, discoloration, weak bonding, or even structural issues over time.

2. How to Choose the Right Solid Surface Adhesive

When selecting solid surface adhesive, consider the following factors:

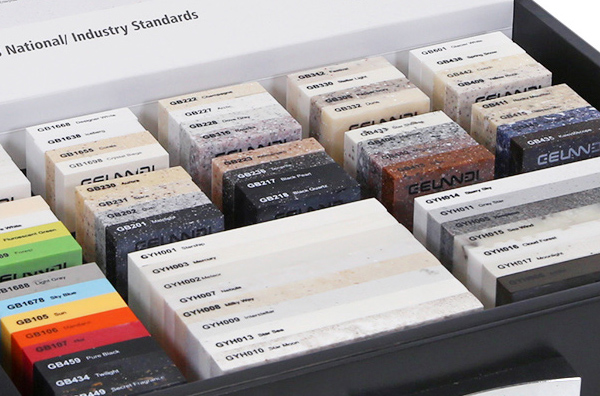

• Color Matching

Choose an adhesive specifically color-matched to your solid surface sheet color. Custom-colored adhesive ensures the seam becomes nearly invisible after polishing.

• Bonding Strength

A reliable two-component (2-part) solid surface adhesive ensures strong bonding strength that can withstand daily use, heat, and impact.

• Curing Time

Faster-curing adhesive can speed up jointing efficiency, while slower-curing formulas provide more open time for complex fabrication.

• Compatibility

Ensure the adhesive is compatible with your specific solid surface material—acrylic, modified acrylic, or polyester blends may require different formulations.Generally, pure acrylic solid surface adhesives can also be used for jointing modified solid surface materials. However, modified acrylic adhesives should not be used for pure acrylic solid surface,

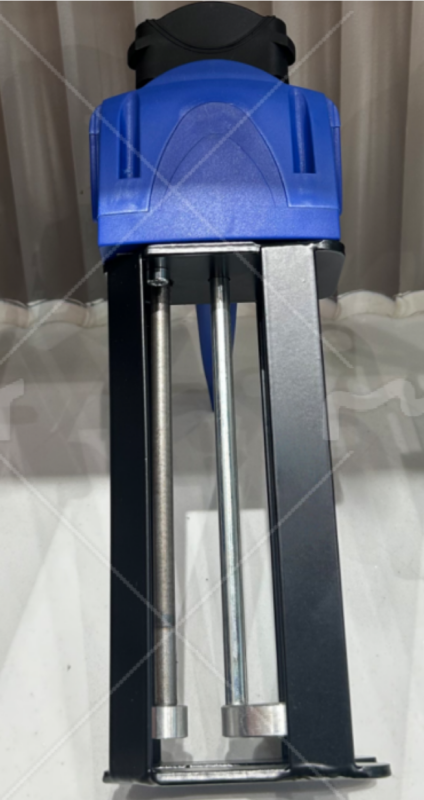

• Packaging and Usability

Cartridge-type adhesives with static mixing nozzles are preferred for clean, consistent jointing. They also help reduce adhesive waste by ensuring accurate mixing and controlled dispensing.

To make fabrication easier for customers, some companies provide adhesive matching services. For example, Gelandy offers color-matched adhesives to ensure seamless joints and a uniform finish.

3. What to Consider When Purchasing Solid Surface Adhesive

·When sourcing adhesive domestically or internationally, keep these points in mind:

·Confirm color-match options before purchasing, especially when using multiple sheet colors

·Check production date and shelf life to avoid weak joints caused by expired adhesive

·Request samples to test color and bonding strength before bulk orders

4. Export Considerations for Solid Surface Adhesives

Solid surface adhesives are typically classified as chemical products, so exporting them requires attention to transportation and documentation:

• Shipping Restrictions

Some components may be classified as hazardous materials and require DG (dangerous goods) handling.

• Proper Packaging

Packaging must meet international standards to prevent leakage or curing due to pressure and temperature changes.

• Customs Documentation

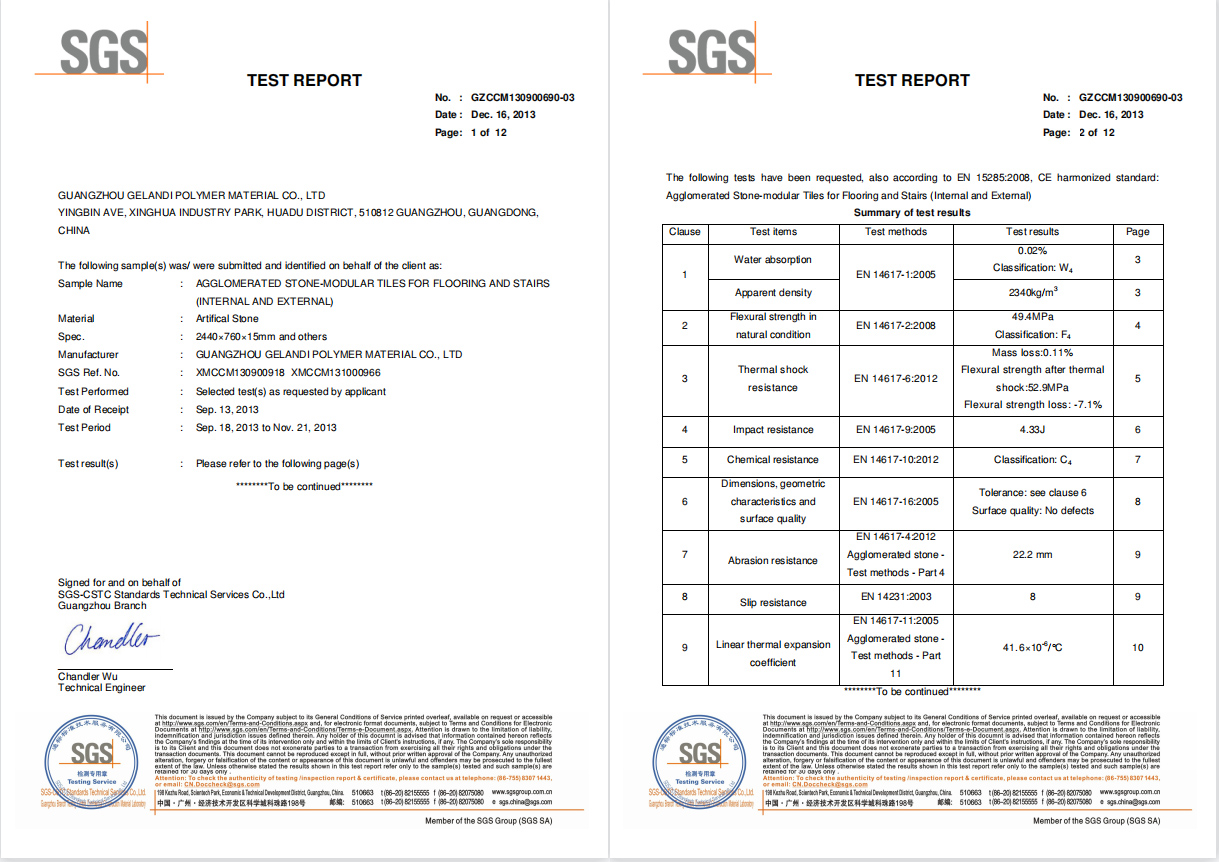

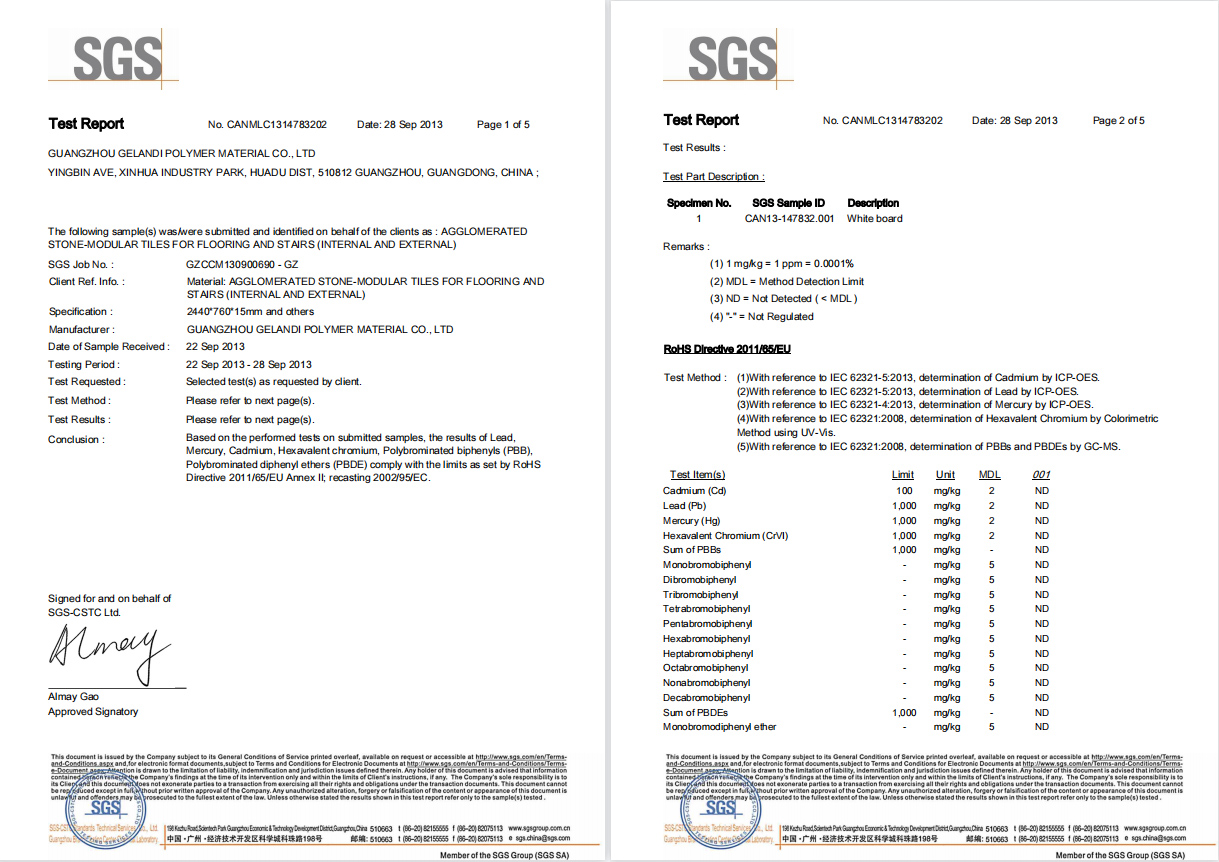

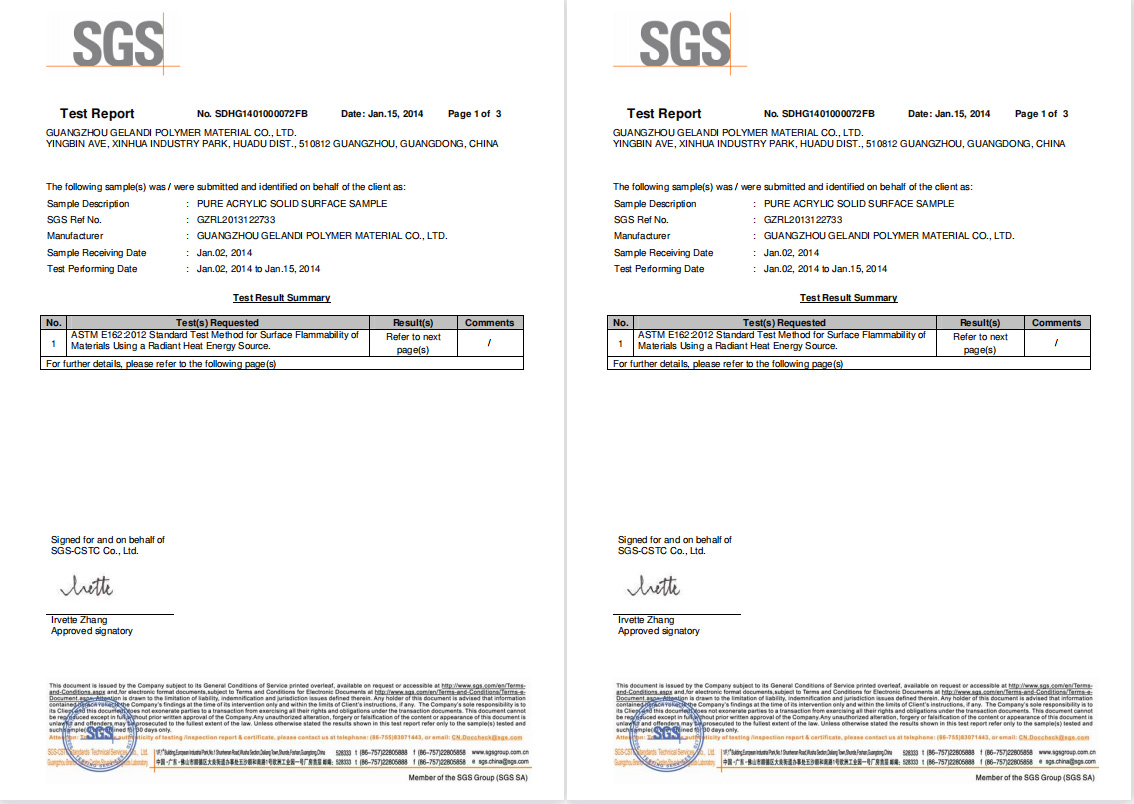

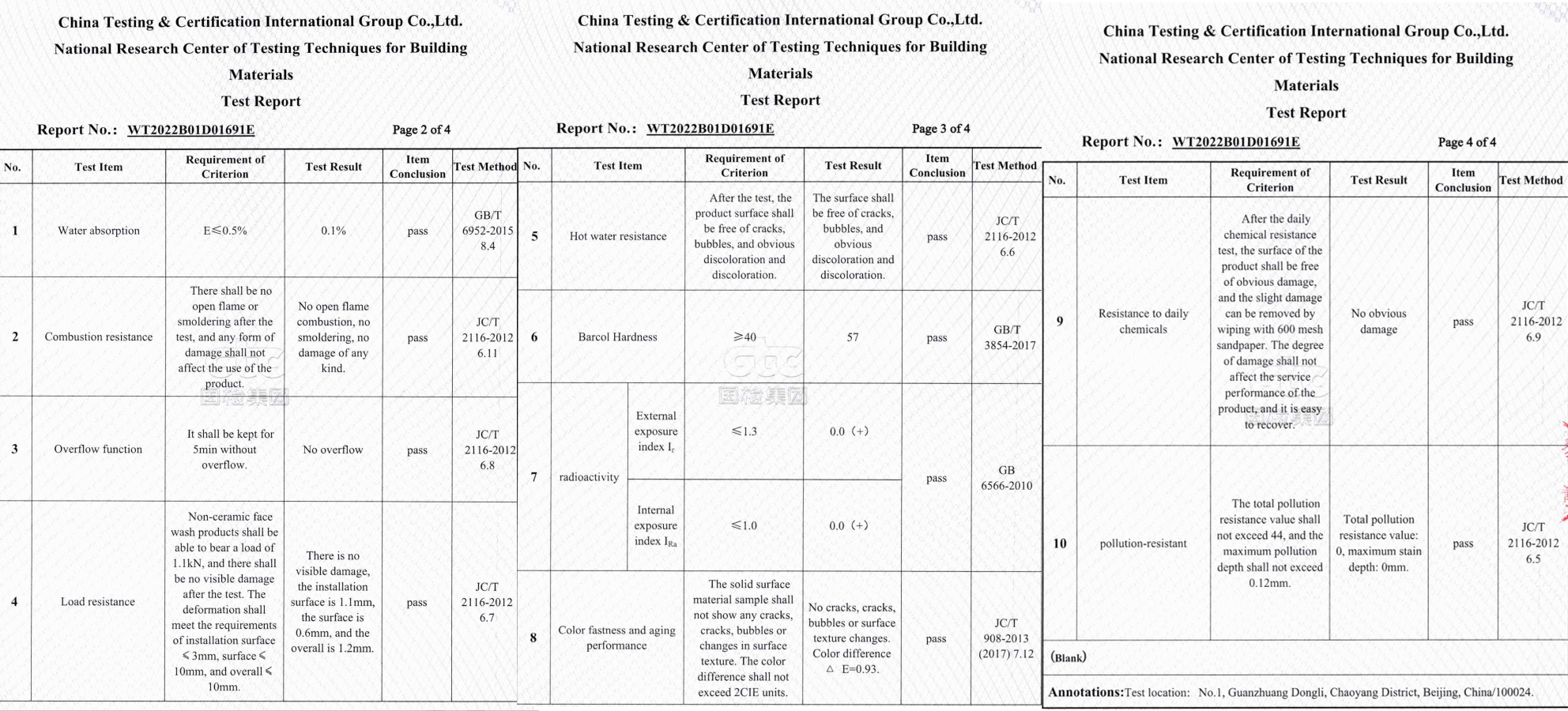

Be sure the destination country’s requirements are met, such as MSDS (Material Safety Data Sheet), COA (Certificate of Analysis), or other compliance documents.

• Temperature Control

Avoid long exposure to high temperatures during transport to maintain adhesive performance.

Selecting the right solid surface adhesive is essential for seamless jointing and durable installation performance. By understanding color matching, bonding strength, and export requirements, buyers can confidently choose adhesives that ensure beautiful and reliable results in every project.

We have always followed the standardization rules for a rigorous production process, saving time and cost for both parties and bringing maximum benefits to you.

A variety of colors and textures, provide OEM&ODM services.

We provide a one-stop service integrating design, measurement, production, delivery, installation, and after-sales service.

Our factory has passed the ISO 9001 international quality certification.

LEAVE A MESSAGE

In the future, GELANDY will always take integrity as the root, quality as the foundation, innovation and development, constantly exceed customer expectations and meet market challenges.