A professional measures the dimensions of the area where the countertop will be installed. A template may be created to ensure an exact fit.

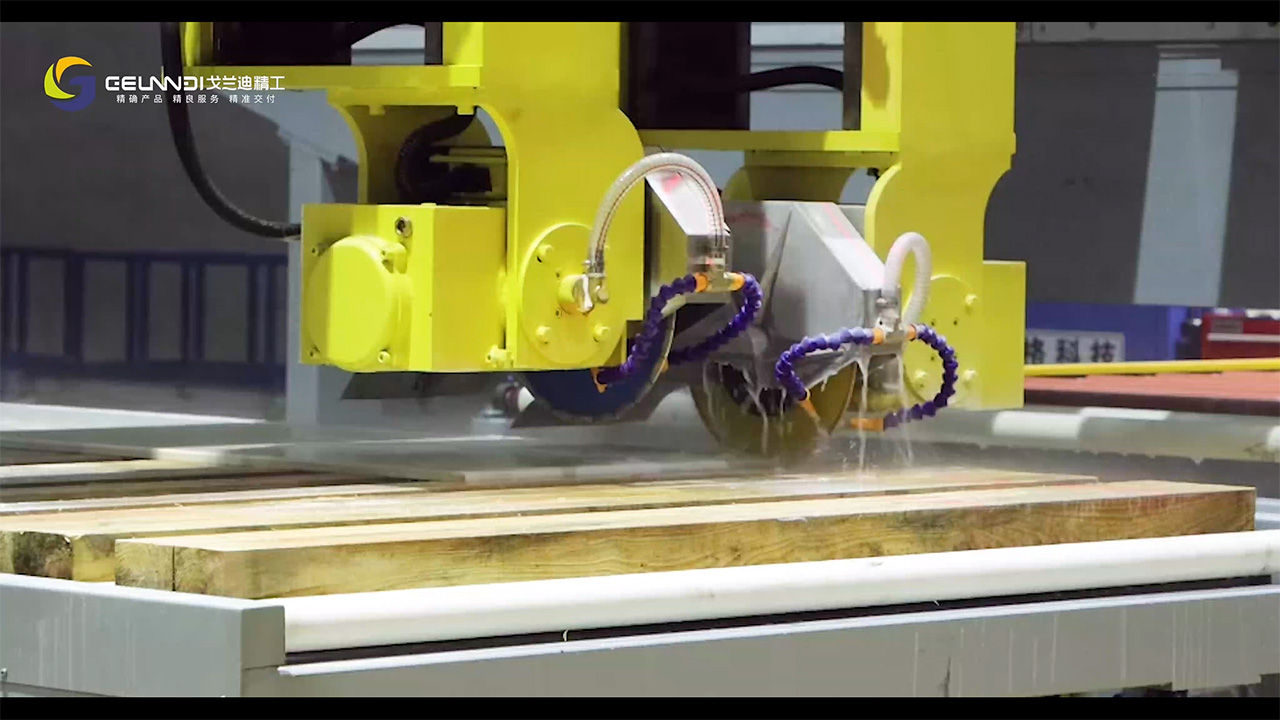

2.Cutting and Shaping Slabs:

Based on the measurements and template, the quartz slabs are cut to the appropriate size using diamond-tipped saws. Any necessary cutouts for sinks or cooktops are made at this stage.

3.Edge Profiling:

The edges of the countertop are shaped and profiled according to the chosen design. Popular edge profiles include bevel, bullnose, and ogee, among others.

4.Seam Placement (If Needed):

For large countertops, multiple slabs may be needed. The fabricator will determine the best placement of seams to minimize their visibility. The seams are carefully joined.

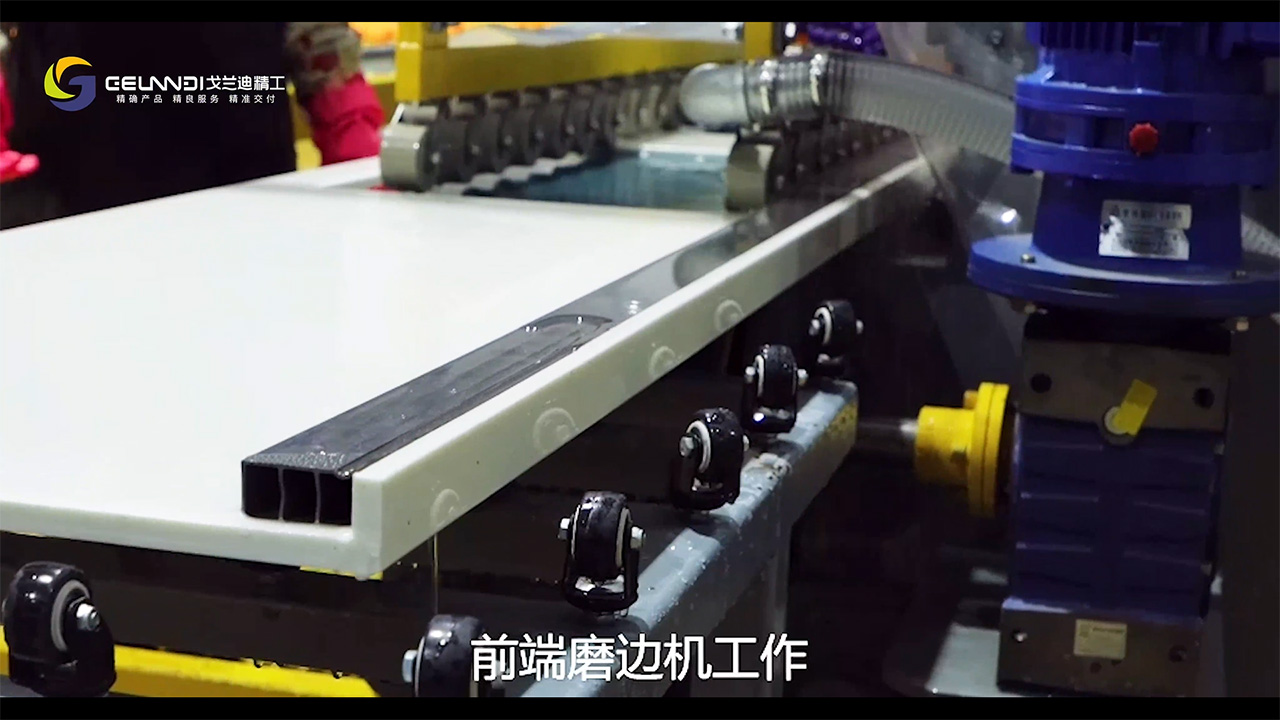

5.Edge Polishing:

The edges of the countertop are polished to match the level of gloss or finish on the top surface.

6.Sink and Faucet Hole Cutouts:

If the countertop includes an under-mount sink or faucet holes, these are cut out and finished to the appropriate size and shape.

7.Backsplash Installation (If Included):

If a backsplash is part of the countertop design, it is installed and secured.

8.Quality Inspection:

The finished countertop is thoroughly inspected for any imperfections or flaws. Any issues are addressed and corrected.

9.Transport and Installation:

The finished countertop is transported to the installation site. It is carefully installed on the cabinets or support structure using adhesive and, if necessary, mechanical fasteners.

10.Sealing (Optional):

While quartz is generally considered low maintenance, some fabricators may apply a sealer to the countertop to enhance its stain resistance, although many quartz countertops are engineered to be non-porous and do not require sealing.

11.Final Inspection and Clean-Up:

The countertop is given a final inspection to ensure it meets quality standards. Any adhesive or residue is cleaned up, and the area is left clean and ready for use.

The specific steps may vary slightly based on the design and requirements of the countertop, but this general process is followed when converting quartz slabs into finished countertops for installation.

Gelandy is the professional quartz slabs and finished quartz countertops manufacturer.We have Quartz stone slab production workshop, Solid surface sheet workshop, Bathroom production workshop, Fabrication workshop.Not only the slabs and sheets,We also process the finished countertops.It depends on your particular needs and service situation.If you are looking for a more convenient and quicker solution,then finished solid surface countertops may be the better option.

For the bathroom ,we provide customized integrated wash basin, pedestal basins, offer a complete product that requires minimal installation and is ready for use.