The processing of quartz countertops

Good countertops require not only high-quality quartz stone slabs but also excellent countertop processing techniques. Today, I will show you the processing workflow for quartz countertops. Currently, the processing of quartz countertops has become mechanized and automated, while the installation of the countertops is mostly done manually.

1. Order Planing

First, the factory receives orders from customers and conducts detailed planning. This includes determining the quartz stone colors, dimensions, shapes, edge designs, and any special requirements for the countertops.

2.Processing drawings and Material calculation

Engineers refine and break down the requirements into drawings needed for each processing step, at the same time ,calculate the overall optimal material usage plan.

3. Material Preparation:

After raw quartz slabs received from Gelandy quartz slabs factory, which are usually in standard sizes,quality inspectors check and verify the slabs.

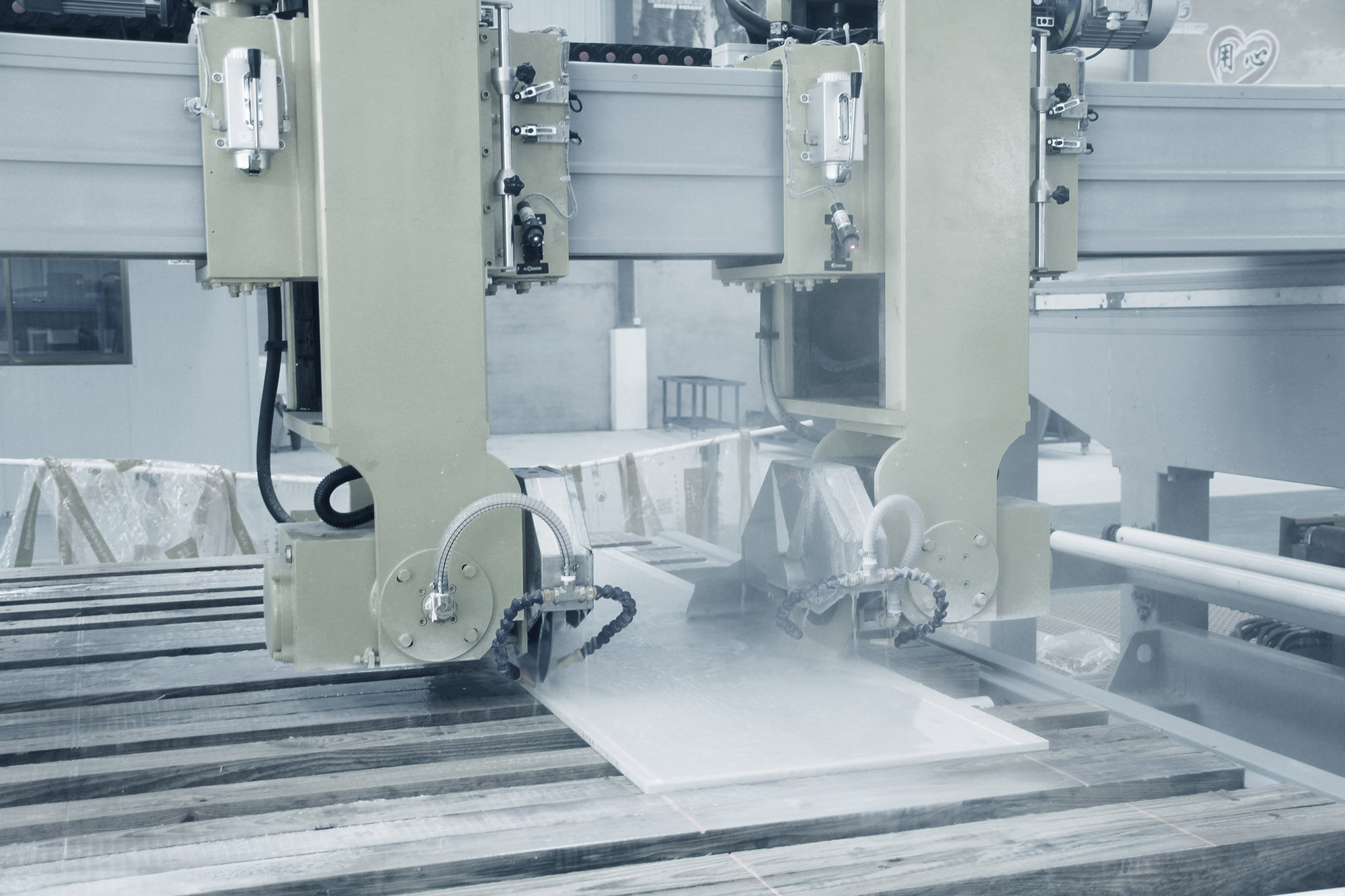

4. Cutting and Shaping:

The processing engineer inputs parameters into the CNC equipment, and the quartz stone slabs are precisely cut and shaped.

5. Grooves and Holes:

Nest,CNC machines cut out grooves for sinks and stove and holes for faucets on the countertops.At the same time, the edges of the grooves and holes are polished smooth. This is one of the important processes to prevent the countertop from cracking.

6.45-degree bevel

8. The 45-degree bevel is primarily to prepare for the subsequent processes: backsplash

joining and front edge hanging joining.

7.Edge Processing:

Then the visible edges are processed. This involves shaping, chamfering, and polishing the edges to ensure smoothness and aesthetics.

8.Backsplash joining.

For exported countertops, to save shipping costs, the backsplash is usually separated.

9. Inspection and Packaging:

Every finished quartz countertop undergoes rigorous quality inspection to ensure it meets customer requirements and standards. Once inspected, the countertops are carefully packaged and prepared for shipment to customers.

The processing of quartz countertops requires precise techniques and specialized equipment to ensure each countertop has consistent quality and aesthetic appeal.