What is the process of the solid surface sheet production

We have introduced the application of solid surface before . Solid surface has strong plasticity such as being bendable and carvable.The solid surface sheets, commonly used for countertops, bathroom vanities, and other applications.In order to further familiarize everyone with solid surface, today we will show you how solid surface sheets are produced.

1. Crushing the granule:

First, crush the solid surface color plate into particles according to the required specifications.This is the unique production process of GELANDY solid surface sheets.(If making solid color sheets, this step is omitted.)

2. Mixing Raw Materials:

Mix acrylic resin with alumina trihydrate and other additives. The ratio and type of materials can vary based on the desired properties of the final product.

3. Casting:

After mixing, automatic cloth laying on the flat mold begins.It’s continuous casting,the mixture is poured onto a continuously moving belt. This method is efficient for producing large volumes of solid surface material.

4.Baking to Curing:

After the material is cast, the flat mold enters the fully automatic vacuum baking oven for baking and shaping, where the sheets are exposed to a controlled heating cycle to polymerize and harden the resin.It’s the curing process.

5.Controlled Cooling:

After curing, the sheets are gradually cooled to room temperature to avoid any internal stresses or deformities in the material.

6.Calibration and Finishing:

Once cooled, the sheets are calibrated to ensure uniform thickness and cut to required sizes.

7. Sanding and Polishing:

After calibration,the sheets are sanded and polished,Gelandy solid surface typically polished to 400 grit before leaving the factory.

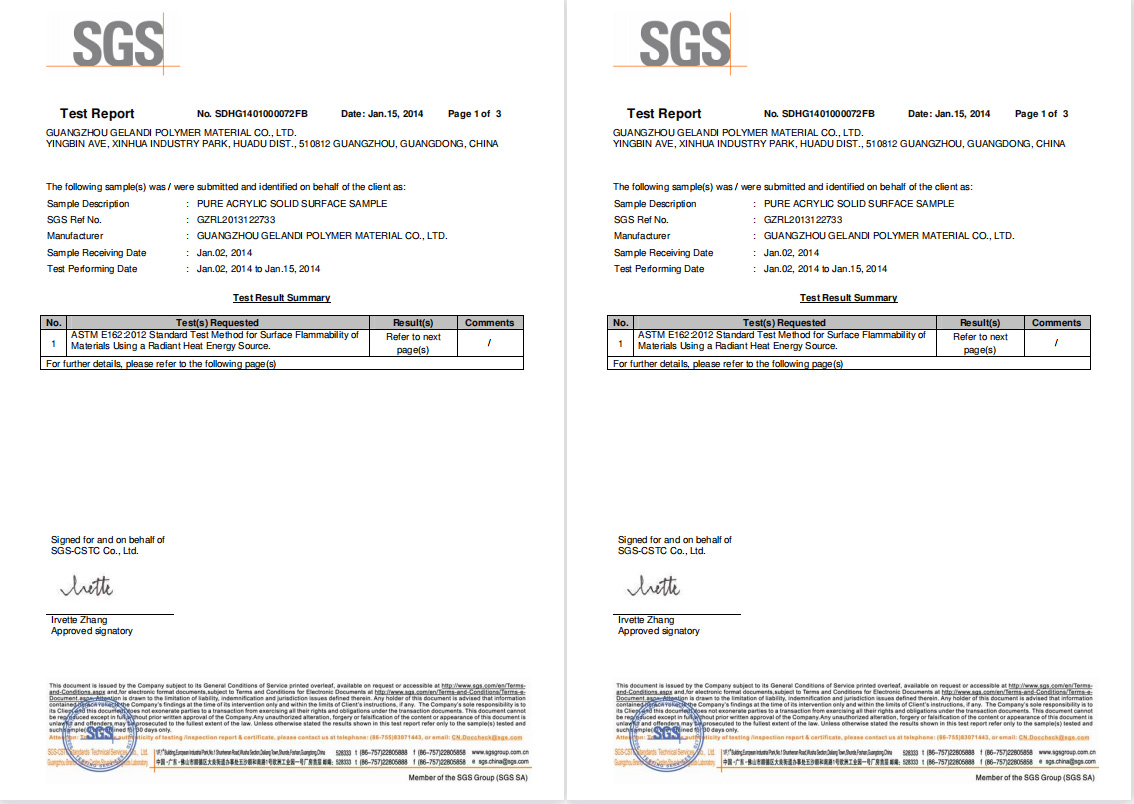

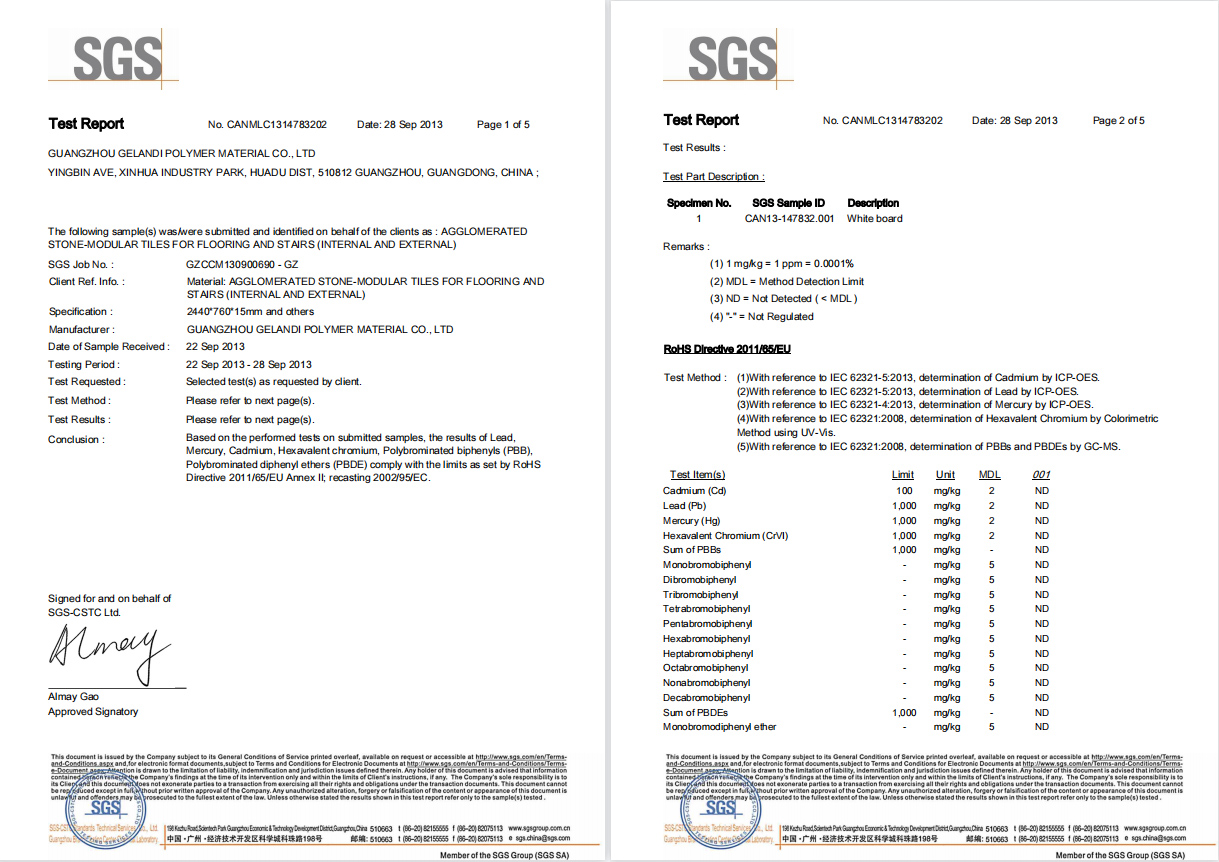

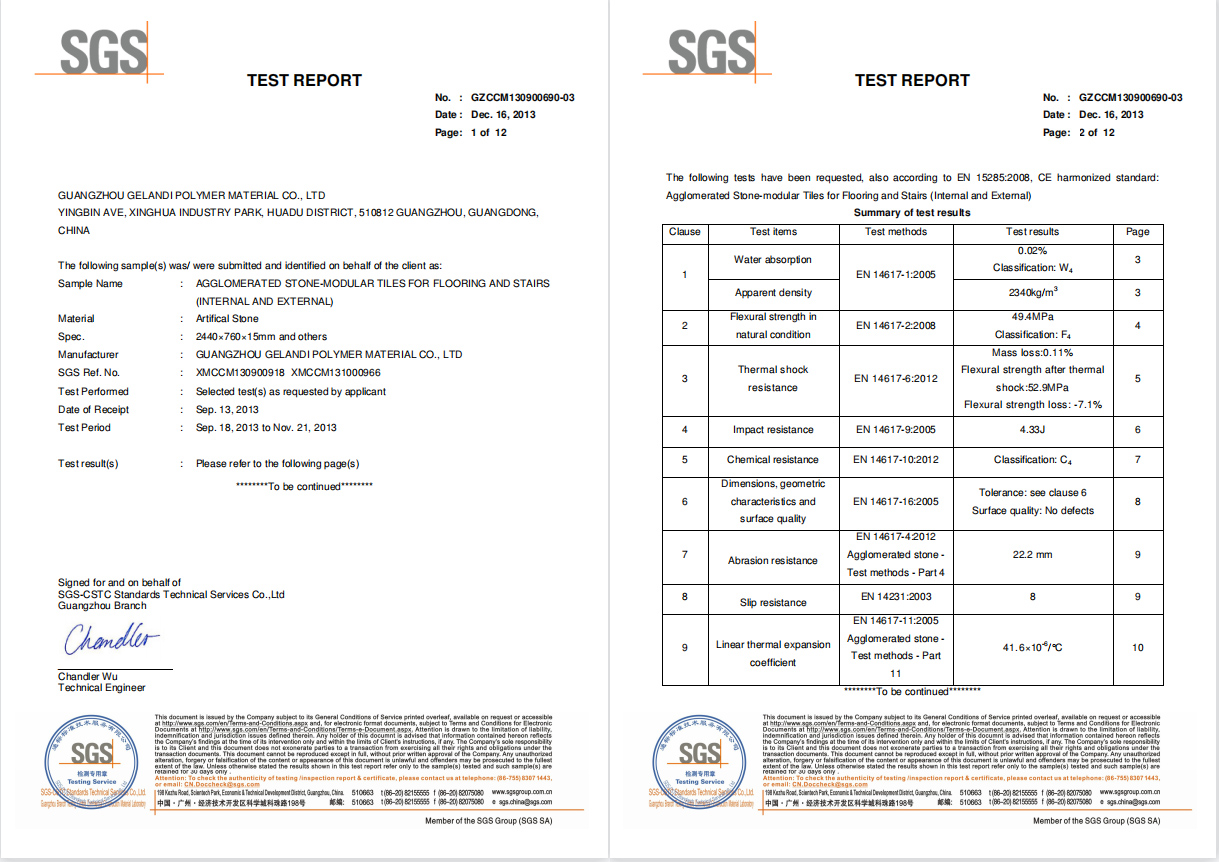

8. Quality Control:

Each sheet undergoes quality control checks to ensure that it meets the manufacturer's standards and specifications. This may include tests for color consistency, strength, and impermeability.

9.Packaging:

After passing quality control, the sheets are packaged and prepared for distribution to the customers.

This production process allows for the creation of highly durable, non-porous, and aesthetically versatile surfaces, making solid surface materials popular in both residential and commercial applications. The annual production capacity of Gelandy solid surface workshop is nearly 1 million square meters per year, including solid color, granular pattern, and vein.